Motor Test Bench

Motor Test Bench is generally used as a reference positioning surface in verification or precision testing. The test platform is suitable for testing the surface flatness of the workpiece by painting, or as an auxiliary tool for experimental work.

Brief introduction and use of motor test platform plate: The test platform is generally used as a reference positioning surface in verification or precision testing.

The test platform is suitable for testing the surface flatness of the workpiece by painting, or as an auxiliary tool for experimental work.

We are great solutions to produce quality Motor Test Bench, as well as other benefits.

The stiffness index of the experimental platform stipulates that the deflection of the flat plate should not exceed 1 m for every 250 (1N=0.102kgf) load applied to the center of the working surface of the experimental platform. During the test, the deflection value of the flat plates at all levels should not exceed half of the flatness tolerance value of the 00-level plates. Various specifications of the experimental platform, the concentrated load area in the center of the working face, the applied rated load and the specific indicators of the allowable deflection value.

Manufactured according to GB/4986-85 standard, the working surface is used for grinding process, used for the grinding of parts, measuring tool repair, the surface roughness Ra≦0.08μm of the parts after grinding with this product, the general size and weight are small, the specifications are in 100×100–800×600, about 30-50 kg, mainly used as the backing plate of the mold. In order to reduce the production cost of the test platform, so that the price of the test platform can occupy the market in the competition, 99.8% of the test platform manufacturers have adopted the manual scraping and grinding process. Although manual scraping and grinding are relatively backward, for the experimental platform, in the case of relatively high precision requirements, it is a processing technology that cannot be replaced by any mechanical processing.

In order to improve the service life of the experimental platform and ensure its working accuracy, it is recommended to control the scraping and grinding depth above 0.02mm, which can ensure that the experimental platform has a long service life and verification period. According to the introduction of the scraping depth and the measured data of the scraping depth according to the relevant information, the processing requirements of this process can be achieved.

Vibration lines appear on the appearance of the experimental platform, and the surface roughness of the product increases, which affects the accuracy and also affects the appearance. With the scraping and grinding process, the above problems rarely occur. Prevent small-scale local distortion on the working surface of the test platform to ensure the accuracy of the test platform. Check the microscopic quality of the working surface of the experimental platform, that is, the flatness of the tiny peaks and valleys. Only with high surface microscopic quality and good wear resistance can the service life of the experimental platform be guaranteed.

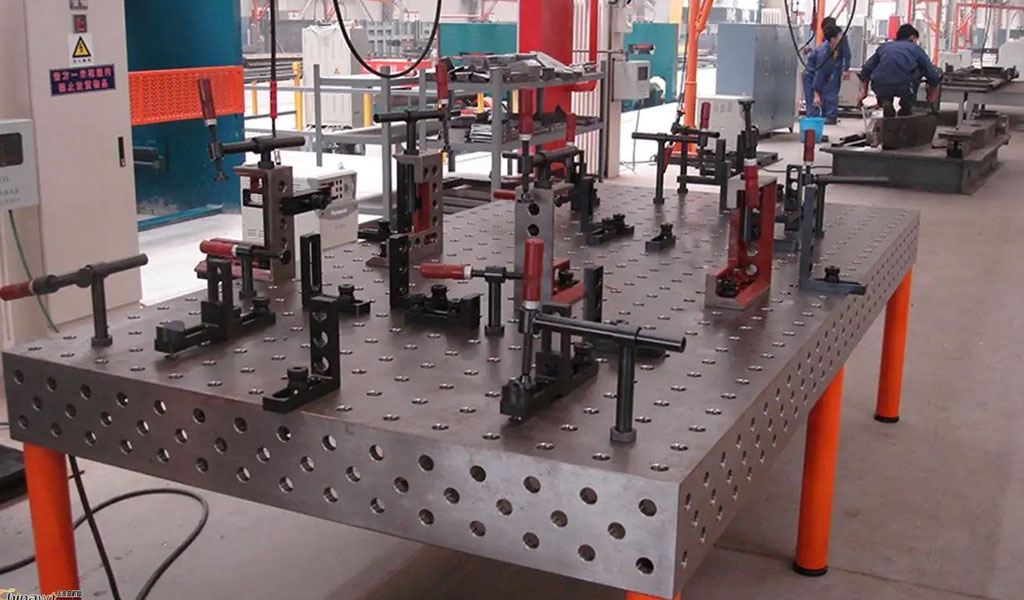

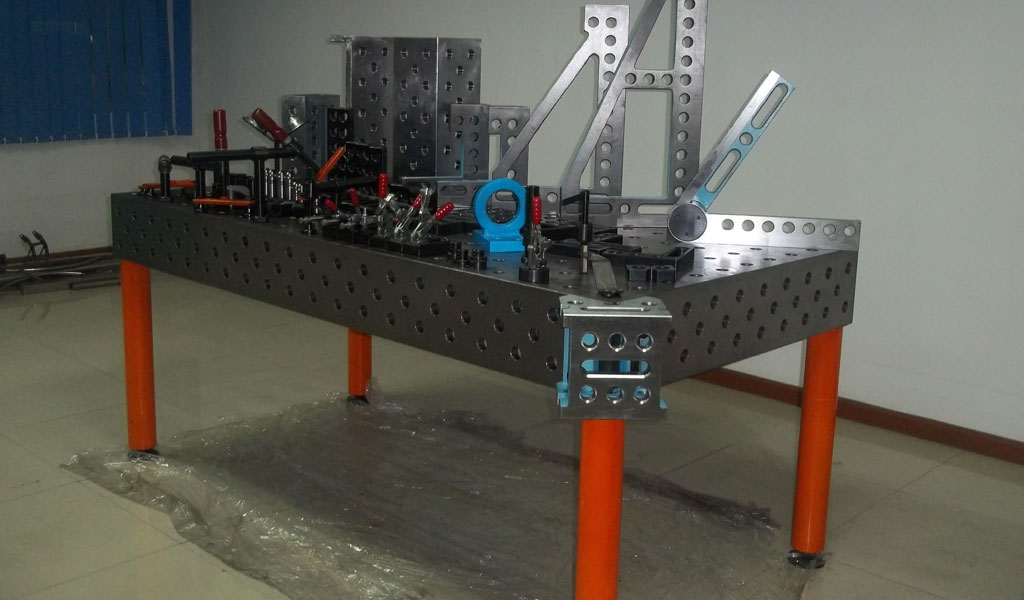

Cast iron motor test bench: There can be holes or T-slots on it to fix the workpiece, and to clean up the iron filings generated during processing or put fixed pins. It can also be designed to be flat. Test platform material: high strength cast iron HT200-HT300 workbench generally has a hardness of HB170-240, and its hardness is better than HB190. Manufactured to 1999 standards. Cast iron motor test bench is mainly used for testing, splicing, and other mechanical purposes of various machinery and other products. The specifications are divided into: 1000×1000mm; 1500×1000 mm; mm;3000×2000 mm;4000×2000 mm;4000×2500 mm;4000×3000 mm;5000×2000 mm;5000×2500 mm;5000×3000 mm;6000×2000 mm;6000×2500 mm;6000×3000 mm; 8000×3000 mm…..

Standard Features and Uses

- Production standard of cast iron test plate: manufactured according to the national GB7947-1999 standard.

Motor test platform

Motor test platform - The shape and structure of the test platform: the shape of the working surface is divided into rectangle, square or circle, and the working surface can be processed with V-shaped, T-shaped, U-shaped grooves, round holes, long holes, etc. for different test work needs.

- Purpose of cast iron test platform: It is specifically suitable for power experiments of machinery and engines, and equipment debugging. It has good plane stability and toughness. The surface has T-shaped grooves, which can be used to fix experimental equipment; at the same time, it is suitable for various For the inspection of various products, the cast iron test platform is used to check the dimensional accuracy or behavior deviation of parts, and it is also an indispensable basic tool in machinery manufacturing as a precision scribing test platform.

- The specifications of the cast iron test platform are: 200300—40009000mm