Stainless Steel Casting

BE-CU is known as a investment casting services supplier, we also provide excellent cnc machining with outstanding properties and performance. A wide variety of stainless steel investment castings are provided, the built-in chromium oxide layer of the castings provides excellent corrosion resistance, which makes stainless steel castings ideal for mechanical, industrial, military, and more industries and fields, whether investment casting hollow parts or solid parts, we can deliver intricate shapes that perfectly match your designs, smooth surface finish is achievable through different metal finishing methods and CNC techniques. High durability makes our stainless steel investment casting parts ideal for high wear applications. Parts manufactured with investment casting service or lost wax casting include hollow parts and other complex geometry based on the part drawing, and the process can achieve excellent detail without multiple processing.

We have strong technical strength and rich experience in product development, and are regarded by customers as a close partner for product development and production. BE-CU’s professional team can provide optimized solutions for products, shorten development time, reduce product costs, and provide customers with reliable one-stop solutions from product design to final products by virtue of manufacturing capabilities. In the past 30 years, BE-CU foundry has successfully manufactured more than 32,000 new stainless steel precision castings in the investment casting industry according to customers’ drawings in more than 10 industries. These parts are delivered to customers around the world by ship, plane and train in EWX, FOB, CIF and DDP. Whether it is design assistance, or transportation arrangements, we are confident to provide you with feasible suggestions and improvement plans based on our accumulated knowledge and experience in different industrial applications and foreign trade operations.

BE-CU Foundry will ensure the quality and performance of the stainless steel lost wax casting products to be delivered.

-

304 Stainless Steel Precision Casting Agricultural Machinery Parts

-

304-303 Stainless Steel Lost Wax Casting Bracelet Or Buckle

-

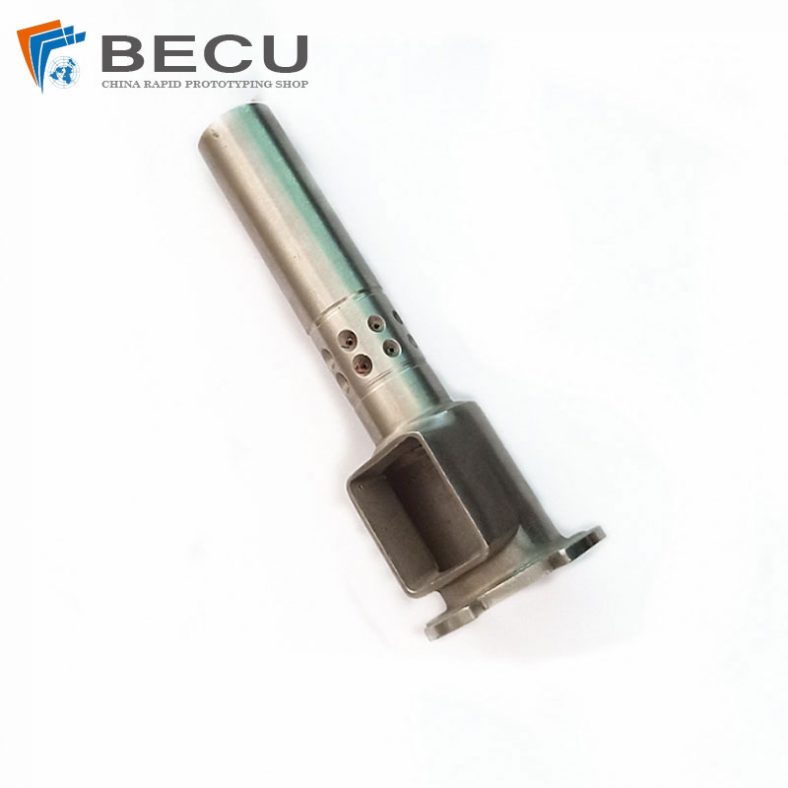

Investment Casting Stainless Steel Oil Press Chamber Rod

-

304 Stainless Steel Sand Casting Components

-

Lost Wax Casting Badminton Racket Pulling Machine Accessories

-

Lost Foam Casting 316 304 Stainless Steel High Heels Accessories

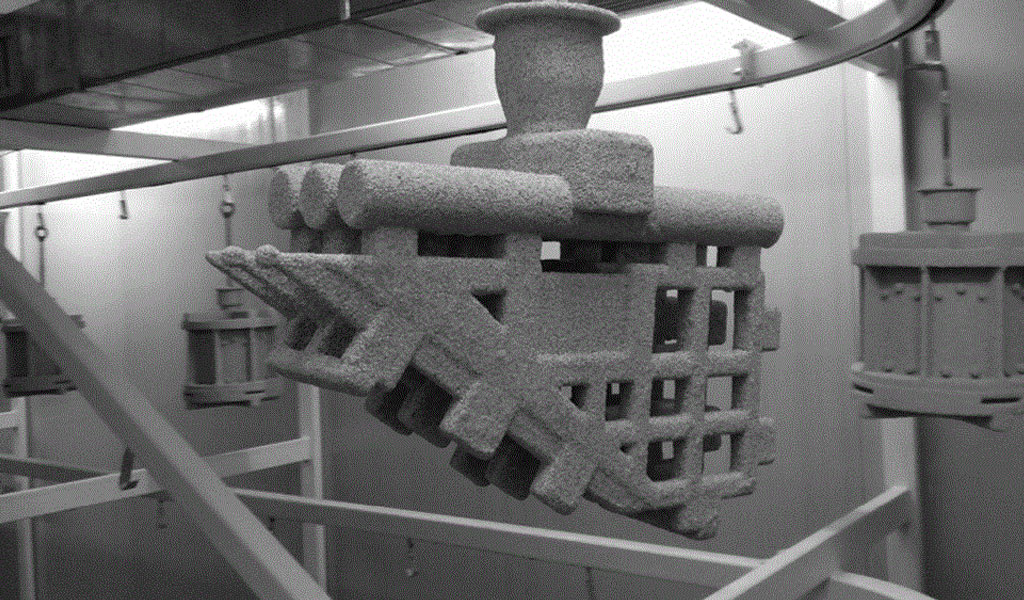

Mass Production Stainless Steel Castings Of Complex Shapes

Benefits Of Making Lost Wax + Secondary Processing

At the prototype stage, there are many cases where the cost becomes a bottleneck when moving to mass production of complicated stainless steel casting products that have been cut. Although it is possible to make some ingenuity with jigs, it can be said that the volume merit at the time of mass production by cutting is small, unlike mass production by making dies such as presses.

Lost wax is considered as a processing alternative in that case. By mass-producing the large frame shape with lost wax from the mold and performing secondary finishing processing, it is possible to significantly reduce the man-hours and costs during mass production.

In particular, it can be said that there are merits in mass production of stainless steel processed products with complicated shapes, which are difficult to cut by cutting alone.

What Is Stainless Steel Casting – Define Of Stainless Steel Cast

Stainless steel casting, or stainless steel investment casting, is the lost wax investment casting process by invests the wax pattern with refractory materials to form the mold, and the molten material is cast into the die.Silica sol process stainless steel casting belongs to investment precision casting or precision casting. It is a casting process with little or no cutting, and is an excellent process technology in the foundry industry. The stainless steel investment casting process, in short, is to use fusible materials (such as wax or plastic) to make fusible models (referred to as investment models or models), and coat them with several layers of special refractory coatings, which are dried and hardened. After forming an integral mold shell, the mold is melted from the mold shell with steam or hot water, and then the mold shell is placed in a sand box, filled with dry sand molding around it, and finally the mold is placed in a roasting furnace for high temperature. Roasting (for example, when a high-strength mold is used, the mold after demolding can be directly fired without modeling), after the mold or mold is fired, molten stainless steel is poured into it to obtain a casting.

Stainless steel casting is not only suitable for casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other casting methods, and even complex, high temperature resistant and difficult to process castings that are difficult to be cast by other casting methods. , can be cast by investment casting.

The dimensional accuracy of investment castings is relatively high, generally reaching CT4-6 (CT10~13 for sand casting and CT5~7 for die casting). Of course, due to the complex process of investment casting, there are many factors that affect the dimensional accuracy of castings, such as mold The shrinkage of the material, the deformation of the investment mold, the linear change of the shell during heating and cooling, the shrinkage rate of the alloy, and the deformation of the casting during the solidification process, etc., so the dimensional accuracy of ordinary investment castings is high, but its Consistency still needs to be improved (castings with medium and high temperature waxes are much more dimensionally consistent).

When pressing the investment mold, a mold with a high surface finish of the cavity is used, so the surface finish of the investment mold is also relatively high.

In addition, the shell is made of high temperature-resistant special binder and refractory paint prepared from refractory materials, which is coated and hung on the investment mold, and the inner surface of the cavity that is in direct contact with the molten metal has a high smoothness.

Therefore, the surface finish of investment castings is higher than that of general castings, generally reaching Ra.1.6~3.2μm.

The biggest advantage of investment casting is that due to the high dimensional accuracy and surface finish of investment castings, machining work can be reduced, but only a small amount of machining allowance can be left on the parts with higher requirements, and even some castings only Leave grinding, polishing allowance, can be used without machining. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing time, and greatly save metal raw materials.

Another advantage of the investment casting method is that it can cast complex castings of various alloys, especially superalloy castings. For example, the blade of a jet engine has a streamlined outline and an inner cavity for cooling, which can hardly be formed by machining. The investment casting process can not only achieve mass production and ensure the consistency of castings, but also avoid the stress concentration of residual knife lines after machining.