Aluminum Casting

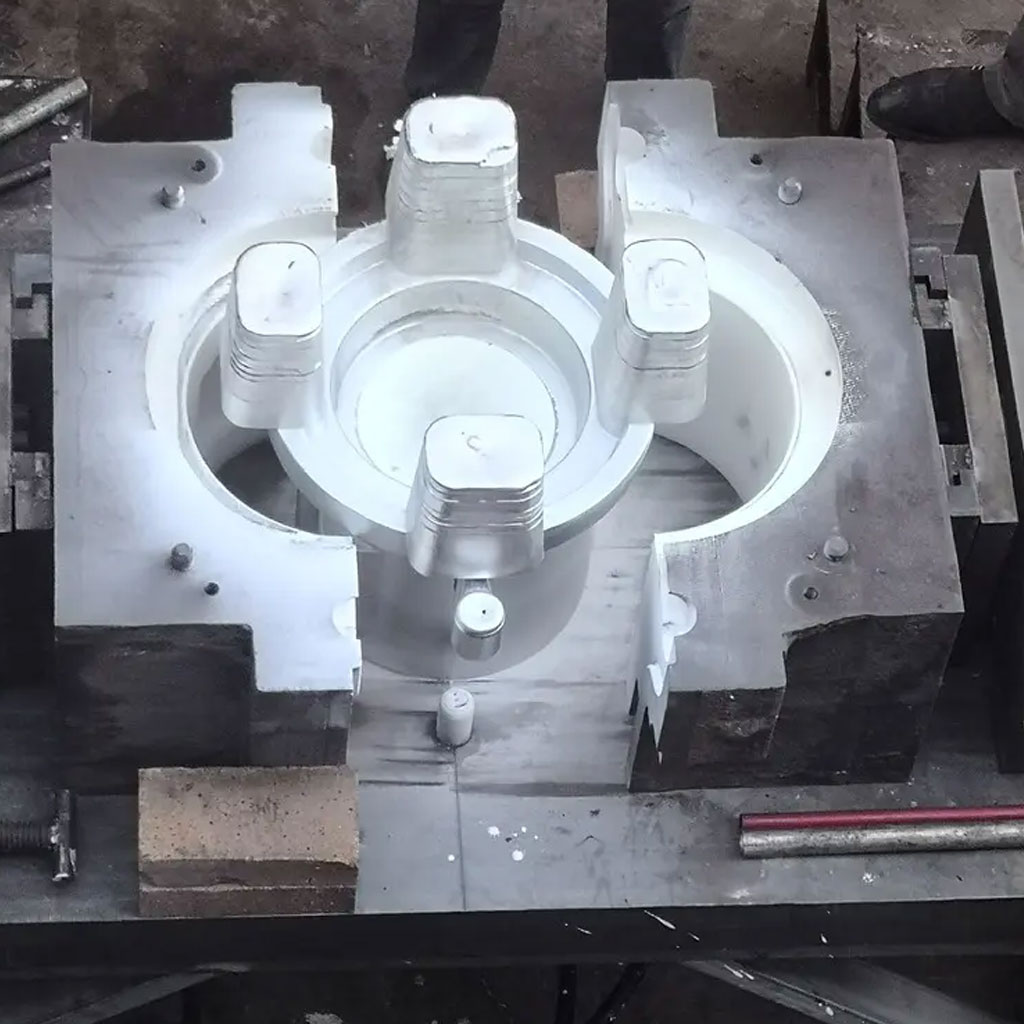

Working with seasoned and reliable in-house subsidiary, BE-CU develops an extensive range of precision aluminum casting components supporting different industries and meeting varying requirements. We offer custom aluminum investment castings,high pressure aluminum die castings,Aluminum Gravity Die Castings and Aluminum Sand Casting Parts for automotive, electronics, aerospace, food, engineering equipment, machinery, etc. Common aluminum castings such as pump impellers, casing, covers, engine parts, transmission parts, axle assemblies, safety fittings, control valves, rotary plug valves, rock handles, cams, brackets, hydraulic machine parts, connectors, and OEM metal castings are all available at China with a short lead time and affordable prices.Contact us to know more about our casting services, which enables us to send you an economical solution for your project in lots of industries.

We have up-to-date Casting Machine, CNC machining center, lathes, milling machine, drilling machine, wire cutting machine, and coordinate measuring machine to ensure your product feature and quality in accordance with customer needs. There are also roughness tester, projector, and other measuring equipment to confirm the exact dimensions and specifications as design. Short lead time and fast delivery make us win good reviews from worldwide clients.

The manufacturing facilities and cast products will be thoroughly tested using advanced testing and measurement equipment to ensure their functions and specifications, we are always trying our best to deliver the best-quality investment castings and machined components. If you require complex or intricate components for defense and medical applications, such as thin-wall castings, we can also manufacture casting parts according to your design and ensure the products in line with industry standards.

What Is Aluminum Casting – The Type Of Aluminum Casting

Compared with steel materials, aluminum alloy materials have been widely used in many industries due to their better specific strength, specific stiffness, corrosion resistance and fatigue resistance, especially in the production of aluminum alloy investment castings in recent years. The scale and output increased rapidly, and a large number of production enterprises appeared. Just like in the modern aerospace industry, the components required for aircraft manufacturing have high requirements in terms of quality, strength, and overall structural performance. Aluminum alloy investment castings are used in them, and the utilization of technology development has been extended and developed.

Investment casting mainly refers to making wax into corresponding models, and smearing clay with refractory properties on the outside of the wax model, and then drying and heating the wax model until the fire melts all the wax, and all the wax oil flows out. , to obtain an empty shell wrapped by a refractory material. On this basis, all the required golden house materials are melted and poured into the hollow shell wrapped by the refractory material, and corresponding measures are taken to cool the metal. Finally, the refractory material outside the metal after cooling is broken into pieces to obtain the material Metal model inside. In modern society, the use of aluminum alloy investment casting technology is an important means to widely use it in the manufacture of machinery and equipment. The following are several types of aluminum casting:

Aluminum Investment Casting

Through in-depth analysis of aluminum alloy investment casting technology, it is found that in the application process of aluminum alloy investment casting, the performance of the model material selected for precision casting and the quality of the wax mold will affect the final aluminum alloy surface. the roughness of the formation. The reason is that the material properties of aluminum alloy materials are reflected in its low density and low melting point. In relatively dry air, the metal material will automatically form an oxide film with protective properties, which cannot pass through the wax mold and casting wall. The tiny holes on it are replicated. Therefore, after the aluminum alloy investment casting, its surface is relatively uneven. In order to meet the needs of modern heavy industry for large-scale castings with thin walls and complex structures, the current technology research and development department has been committed to researching film materials with high strength and good performance that are not easy to shrink and deform, such as water-soluble core forming, liquid mold material high pressure Injection molding and other technologies have been rapidly developed, applied and developed. In terms of technical application, the continuous improvement of the production and development of wax pressing equipment, the emergence of large wax pressing machines provides conditions for the manufacture of large investment parts, such as the V-3002 wax pressing machine produced by TEMPCRAFT in the United States, the maximum forming force can be up to 3000kN. This technology has been widely used in the production of mechanical equipment parts, such as the production of investment casting technology medium-pressure wax machine investment parts.

Gypsum Investment Casting For Aluminum

In the process of analysis of aluminum alloy investment casting technology, this paper believes that Shiyu investment casting technology is one of the more commonly used technologies in this technology. Gypsum investment casting technology usually uses hot mold casting in the casting process, which easily leads to uneven thickness of the cast castings. During the application of gypsum investment casting technology, the standardization of the technical operation should be strengthened, the mixing standard of gypsum powder and water should be clarified, and the guarantor should realize stirring in a vacuum environment to ensure the reliability of the process quality. The advantage of gypsum mold volume casting technology lies in its good reproducibility, so it can be applied to castings that require high dimensional accuracy, but the surface roughness requirements of the castings cannot be too high; hot mold casting for gypsum mold investment casting applications, thermal conductivity It is not high, so it is possible to pour out the uniformity of the original white wall.

Ceramic Investment Casting For Aluminum

In the process of analysis of aluminum alloy investment casting technology, this paper believes that Shiyu investment casting technology is one of the more commonly used technologies in this technology. Gypsum investment casting technology usually uses hot mold casting in the casting process, which easily leads to uneven thickness of the cast castings. During the application of gypsum investment casting technology, the standardization of the technical operation should be strengthened, the mixing standard of gypsum powder and water should be clarified, and the guarantor should realize stirring in a vacuum environment to ensure the reliability of the process quality. The advantage of gypsum mold volume casting technology lies in its good reproducibility, so it can be applied to castings that require high dimensional accuracy, but the surface roughness requirements of the castings cannot be too high; hot mold casting for gypsum mold investment casting applications, thermal conductivity It is not high, so it is possible to pour out the uniformity of the original white wall.

High Pressure Aluminum Die Casting

The use of aluminum alloy die-casting parts reduces the quality of the car, reduces fuel consumption and reduces exhaust gas; and the die-casting parts have the advantages of noise reduction and vibration reduction and high casting accuracy. my country’s automobile industry has grown rapidly in recent years, and the demand for aluminum alloy investment die castings has increased rapidly, which has greatly promoted the development of my country’s aluminum alloy die casting industry. Die-casting aluminum alloys are divided into medium and low strength (such as Y 102 in China) and high strength (such as Y112 in China) according to their properties. Aluminum alloy die-casting has high mechanical properties and can die-cast various complex and thin-walled castings. At present, the die-casting aluminum alloys used in industry mainly include the following series: Al-S-Cu, Al-S-Mg, Al-Si, Al-Mg, Al-Zn, etc. The improvement of the mechanical properties of die-casting aluminum alloys is often accompanied by the reduction of the casting process performance. Due to the characteristics of high-pressure and rapid solidification of die-casting, this contradiction is more prominent in some aspects. In the future promotion and application, we will focus on promoting new high-strength, high-wear-resistant die-casting alloys, and research on colorable die-casting alloys and new die-casting alloy technologies for castings with special safety requirements.

Low Pressure Aluminum Die Casting

In the low pressure die casting process the metal is transferred from an air tight furnace through a rising tube into a metallic tool. The casting temperature is about 750°C.

Low pressure aluminum die casting is competitive casting method when the production quantity is relatively small and/or when heat treatment is needed to improve the mechanical properties. The tolerances and the surface finish are the same as achieved by gravity die casting. The tooling costs are somewhat higher than by sand casting. For its low pressure, this manufacturing process is more suitable for thick aluminum products, even small volume is feasible.

Sand Casting For Aluminum

Sand casting is the most versatile method for producing aluminum products. The process starts with a pattern that is a copy of the finished casting. Virtually any pattern can be pressed into a fine sand mixture to form the mold into which the aluminum is poured. The pattern is slightly larger than the part to be made, to allow for aluminum shrinkage during solidification and cooling. As compared to die and permanent mold casting, sand casting is slow process but usually more economical for small quantities, intricate designs or when a very large casting is required.

The Benefits of Aluminum Castings

- Soft, lightweight, strength-to-weight ratio

- Tractable, malleable, machinability

- Durable, corrosion resistance

- Non-magnetic, non-flammable

- Anodization potential

- Resistant low temperature

- Electrical conductivity

- Recyclability

As one of professional aluminum casting manufacturers from China, BE-CU foundry has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Aluminum material characteristics. So we can offer you the best aluminum casting solution according to your requirements of Aluminum parts and projects.