Magnesium Die Casting

Magnesium alloys are the lightest among metal engineering structural materials, and their applications in the world have been increasing in recent years. In terms of physical properties, the density of pure magnesium is 1.74 g/cm3, which is 1/4 of steel, 1/3 of zinc alloy, and 2/3 of aluminum alloy. Low density, high specific stiffness, high specific strength, excellent shock absorption, stability, electromagnetic shielding, and green environmental protection are the characteristics of magnesium alloys. Every year, the use of magnesium alloys in the world has increased by 20% compared with the same period of the previous year, and the application has continued to increase. The use of magnesium alloys in my country is also increasing. It is precisely because of the wide use of high-performance magnesium alloys in machinery, automobiles, aerospace and other industries that the exploration and research of its casting technology has been put on the agenda.

In recent years, the application of magnesium alloy die-casting (hereinafter referred to as magnesium die-casting) in the automobile industry of developed countries such as Europe, the United States, and Japan has shown a sustained and rapid growth momentum. The average annual increase of more than 15%. At present, the main application field of magnesium is magnesium-aluminum alloy. If the development speed enters the 21st century, magnesium die-casting structural parts will become the most important application field of magnesium. The rapid growth of magnesium die-casting is mainly caused by the challenges faced by the automobile industry in developed countries in Europe and the United States, which require vehicles to be light in weight, low in fuel consumption, and environmentally friendly. The application of magnesium alloy parts can also improve the performance of automobiles, which is also one of the reasons why the automobile industry attaches great importance to the application of magnesium alloys. So, what is magnesium alloy die casting?

What Is Magnesium Die Casting – Define Of Magnesium Die Casting

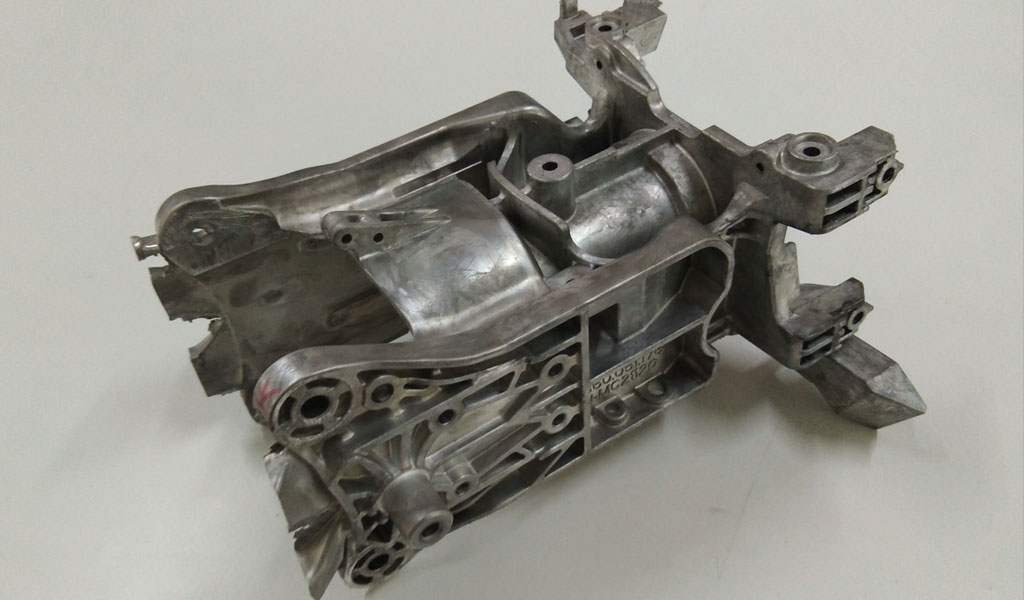

Magnesium Die Casting is a method of using high pressure to extrude magnesium melt into the cavity at a low speed, solidification and slight plastic deformation to obtain castings.

The magnesium alloy castings obtained by this die-casting technology have high density, excellent mechanical properties and high dimensional accuracy, etc., and have a good effect on improving the defects such as porosity and pores of the castings.

In addition, the obtained castings can also be The heat treatment process is directly carried out to obtain finer texture grains.

Superior China Magnesium Die Casting Services Company & Manufacturer

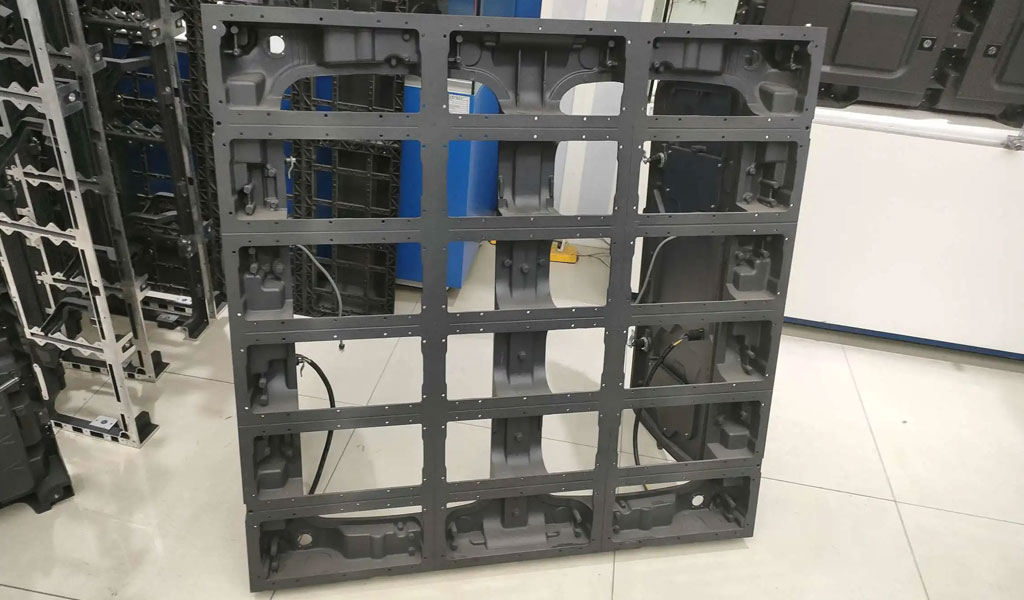

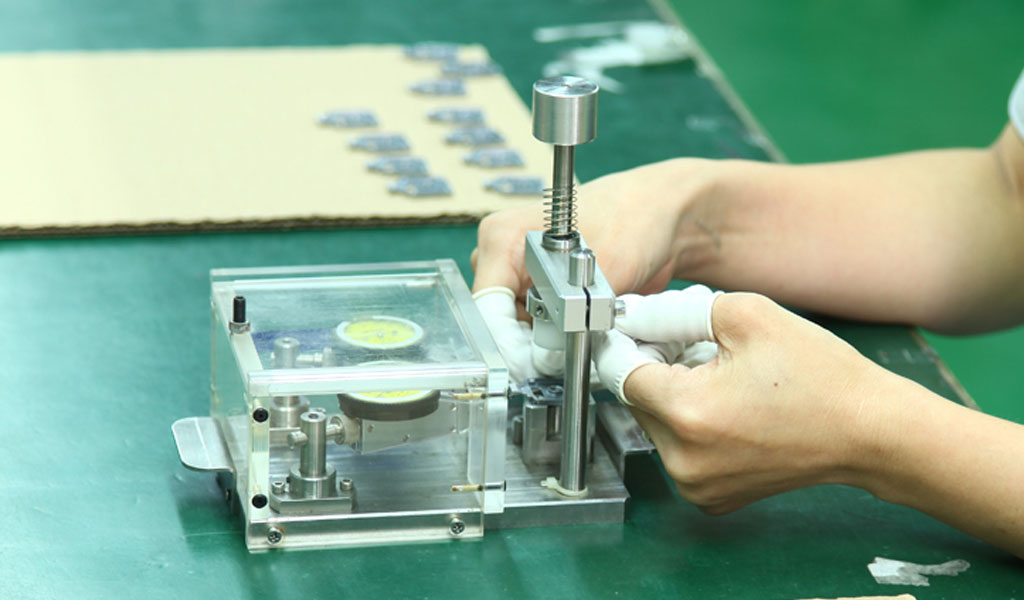

Are you considering a cost-effective magnesium die casting project? Working with Pintejin Foundry – a specialty precision die casting services supplier is the right choice. With over 30 years of experience in metal casting and mold making, we are capable to assist our customers including engineers and designers to bring their magnesium die casting design to a real product that meets or exceeds their expectations, while maintaining the economy of the casting supplies at the same time.Magnesium alloy parts have a maximum weight of 6 kg/13.23 lbs and a maximum size of 700 sq cm/0.753 sq ft. Zinc alloy parts have a maximum weight of 8 kg/17.64 lbs and a maximum size of 950 sq cm/1.023 sq ft. Die castings come with passivation, electroplating, spray painting, powder coating, micro arc anodizing, and silk screen printing surface finishes. Secondary operations include tapping, drilling, and CNC machining. Assembly and packaging services also offered. Small to large volume production. Advanced manufacturing equipment and measuring devices are fully equipped at our casting foundry to enable us to always supply high-quality magnesium die casting parts, zinc die casting parts, metal molds, and casts with competitive prices, innovative design, flexible service, quality assurance, and short delivery time. Our professional technicians and operators will seriously complete each step throughout the production and testing process, to ensure each magnesium die casting product functions normally and can last a long time.

Magnesium Die Casting Services – China Custom Manufacturer Of Magnesium Die Casting

The Advantages Of Magnesium Die Casting

Magnesium die-casting as a high-tech, whether in the automotive industry or in other fields, its main advantages are:

- Light weight;

- Product integration, 30 to 60 parts in the original design can be integrated into one-piece die-casting parts;

- Due to the high elongation of AM series magnesium alloys, it can increase the impact resistance of the components and the storage energy of the anti-collision air bag;

- Reduce processing costs and component assembly costs;

- Reduce vibration and noise;

- Reduce the inventory of parts;

- Improve the rigidity of auto parts;

- Improve the recovery rate of products;

- Increase flexibility in product design.