Welding Platform

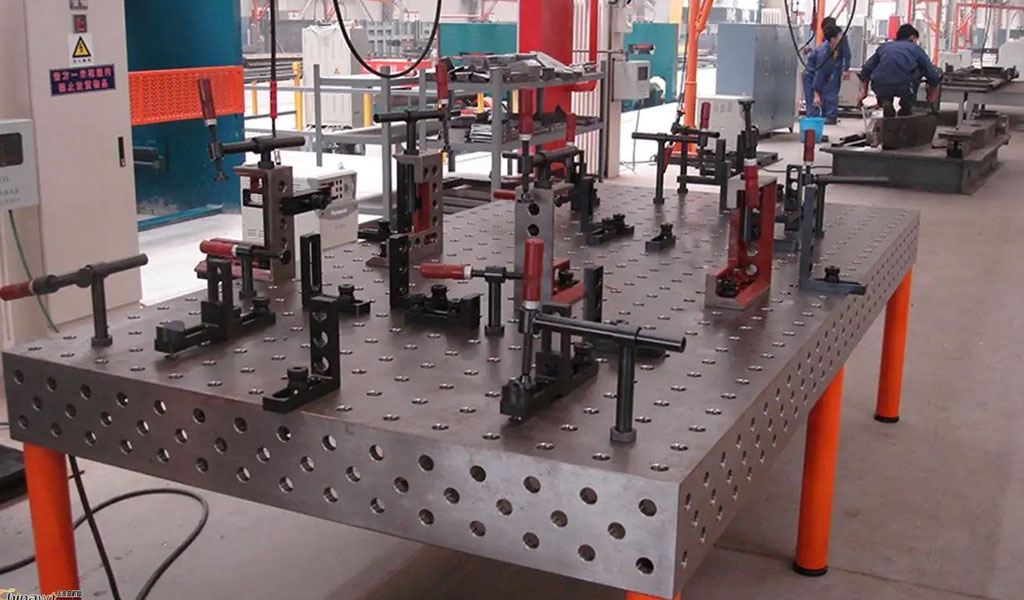

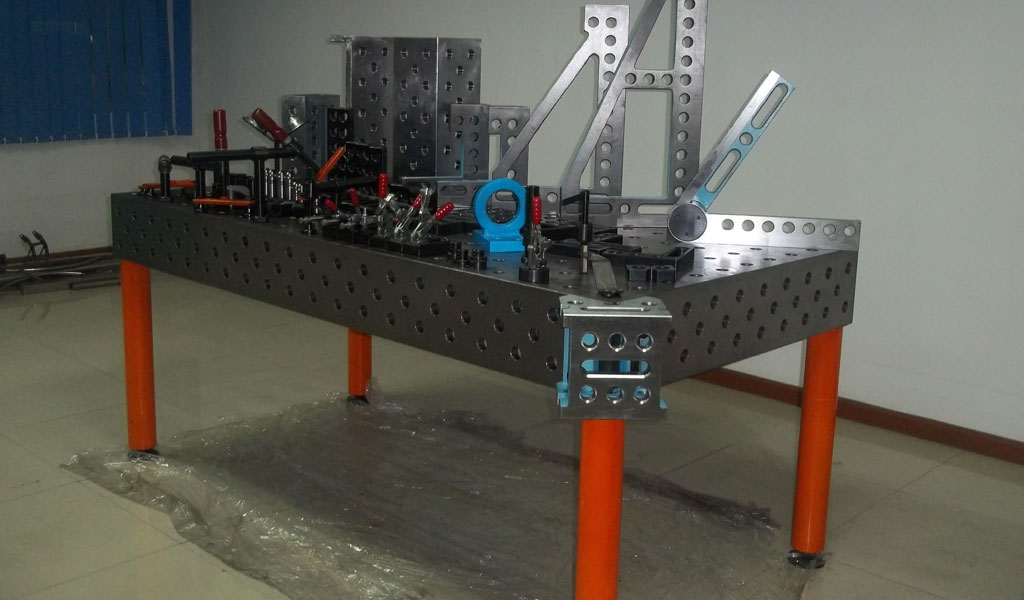

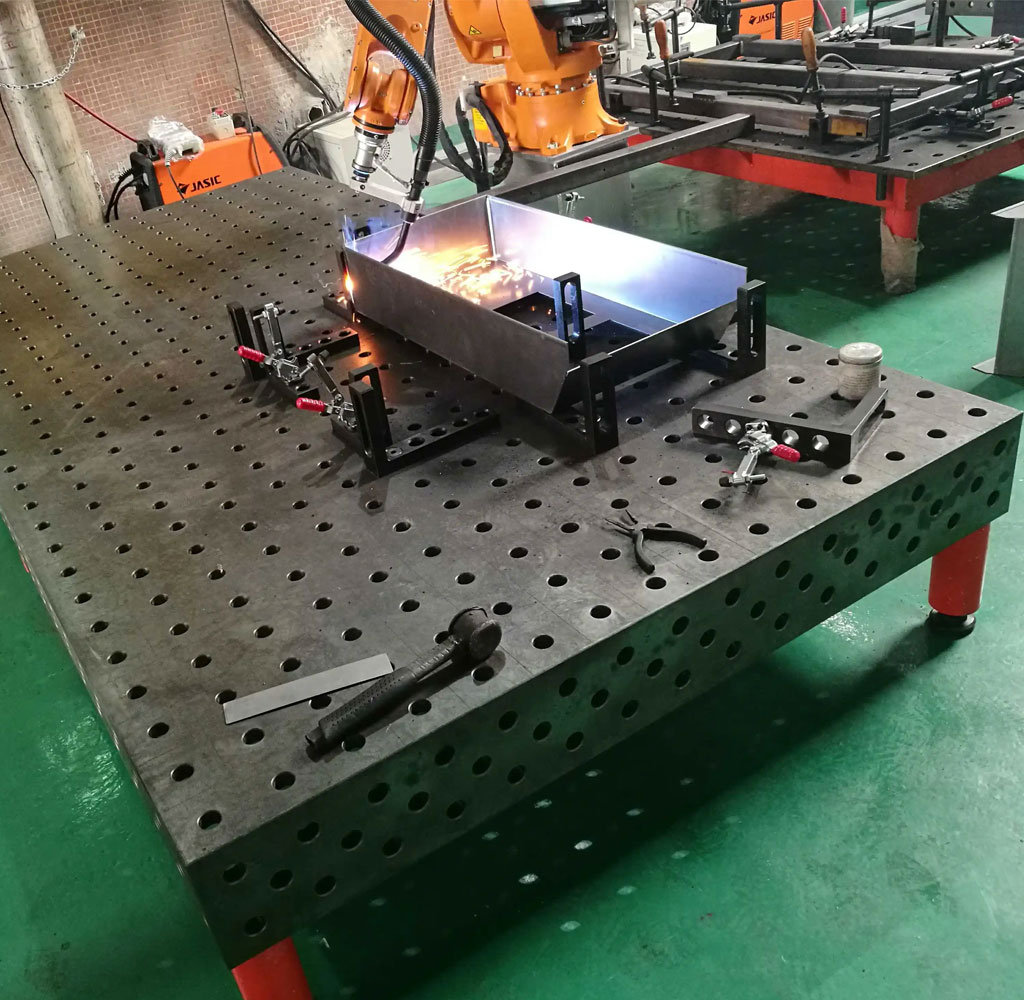

The welding platform is a cast iron plate used for workpiece welding. The working surface is a flat surface or a T-slot, which can be used for fixing. Unlike the riveting plate (riveting platform), there is no hole on it. The welding plate/welding platform has good heat resistance and corrosion resistance.Welding platform is a very commonly used measuring tool and equipment, which is advanced, high-precision, simple and quick to operate welding tooling equipment. The product has strong practicability and can be used repeatedly, which can save investment costs and occupy the mainstream position in welding tooling equipment.

The flexible welding tooling eliminates the designer’s investment in repeated design and production of tooling.

What Is Welding Platform

- Welding plate (welding platform) specification: 100100—400010000, (special specifications are made according to the drawings of the buyer).

- Welding plate (welding platform) accuracy: according to the national standard measurement and verification procedures, with four grades of 0, 1, 2, and 3 respectively.

- The welding platform (welding plate) is used for welding the workpiece. Unlike the riveting plate, there are no holes on it, and the working surface is a flat surface or a T-slot.

- Welding platform material: high-strength cast iron HT200-300 working surface hardness is HB170-240, after two manual treatments (artificial annealing at 600-700 degrees and natural aging for 2-3 years), the product has stable precision and good wear resistance .

- Welding plate accuracy: according to the national standard measurement and verification procedures, with four grades of 0, 1, 2, and 3 respectively.

- During the production process of the welding platform, there will be weight deviations. Often, the design of the welding platform takes into account the casting error and machining error. The weight error of the cast iron platform should generally not exceed 10%. When it exceeds 10%, the quality of the welding platform must be further evaluated to determine whether the cast iron platform can be used.

The Type Of Welding Platform

- Welding plate material: high-strength cast iron HT200-300 working surface hardness is HB170-240, after two manual treatments (artificial annealing at 600-700 degrees and natural aging for 2-3 years), the product has stable precision and good wear resistance .

- Other measuring tools: cast iron plate, basic plate, scribed plate, inspection plate, riveting plate, cast iron plate, pyrotechnic plate, fitter plate, grinding plate, scraping plate, sand pressing plate, test plate, machine tool table (such as: Floor boring machine table), three-coordinate plate, die pad, assembly plate (also called assembly plate). Or: cast iron platform, basic platform, marking platform, inspection platform, riveting and welding platform, cast iron platform, pyrotechnic platform, fitter platform, grinding platform, scraping platform, sand pressing platform, test workbench (such as: vibration test workbench for short Vibration test bench), machine tool workbench (such as: floor boring machine workbench), three-coordinate platform, mold workbench, assembly platform (also called assembly platform).

Inspection Method For Welded Flat Plates

During the production process of the welding platform, there will be weight deviations. Often, the design of the welding platform takes into account the casting error and machining error. The weight error of the cast iron platform should generally not exceed 10%. When it exceeds 10%, the quality of the welding platform must be further evaluated to determine whether the cast iron platform can be used.

- There should be no rust, scratches, bumps and other appearance defects affecting the use on the working surface of the welding platform.

- There should be no casting defects such as sand holes, pores, cracks, slag inclusions and shrinkage porosity on the working surface of the welding platform. The casting surface should be thoroughly cleaned of molding sand, and the surface should be smooth and firmly painted, and the tax edges should be blunt.

- On the opposite sides of the plate, the T-slot should have installation handles or hoisting positions, threaded holes or cylindrical holes. When setting the hoisting position, consideration should be given to minimizing the deformation caused by hoisting.

- The welding platform should be stabilized and demagnetized.

- The vertical tolerance between the working surface and the side surface of the welding platform and the adjacent two sides is 12 (according to GB1184-80 “Shape and Position Tolerance”).

- The hardness of the working surface of the welding platform should be between HB170-220 or 187-255.

Main verification items of T-slot

- A. Material and surface hardness.

- B. Tolerance of shape and position, including nominal size and verticality tolerance.

- C. Appearance.

- D. Flatness.

- E. Contact spots.

- F, plane fluctuation.

- G. The allowable deflection value of the working surface.

- H. Surface roughness.

Precision Parameter

Class 3 slabs do not specify contact spot requirements.

- Class 1 plates require that the number of contact spots be no less than 20 in any 25×25mm plane.

- Class 2 plates require that the number of contact spots be no less than 12 in any 25×25mm plane.

The thickness of the casting panel of the welding platform is not easy to be too thin, which is caused by two reasons:

- How to use the welding platform. The welding platform, as the name suggests, is to perform welding work on the platform. It is inevitable to beat it. The strength of the beating prevents us from using a panel that is too thin.

- The casting method of welding platform castings: If the wall thickness of welding platform castings is too thin, there will be defects such as insufficient casting and cold insulation during the production of castings. This is because an excessively thin wall thickness cannot ensure that the casting alloy liquid has sufficient capacity to fill the mold.

Usually under certain casting conditions, each casting alloy has a minimum wall thickness that can fill the mold, commonly known as the minimum wall thickness of the casting alloy. When designing castings, the design wall thickness of the castings should be not less than the minimum wall thickness. This minimum wall thickness is related to the fluidity of the casting alloy and the contour size of the casting.