3D printing technology is to transform traditional two-dimensional plane printing into three-dimensional space accumulation, and realize the three-dimensional manufacturing of three-dimensional objects. With the development of computer technology, more and more digital models of products have begun to appear. By slicing these three-dimensional digital models into layers, the shape information is solidified with an optical scanning head to solidify the liquid material or the spray head is used to bond the powder material, which is achieved in an additive manner. The layer-by-layer superposition of graphic information finally completes the rapid prototyping of the digital model, so this technology is also called additive manufacturing technology

With the continuous progress of this technology, people’s understanding and research on related fields such as 3D printing process principle, material system and equipment performance have also been further deepened. technical application.

With the years of research and development of online 3D printing technology, the scope of application of materials has gradually expanded, and the degree of automation of equipment has been significantly improved. Many mature and excellent forming process methods have emerged, and the types and properties of products prepared by them have also shown a leap-forward improvement. . At present, 3D printing forming technology mainly includes the following categories:

- Light curing: mainly SLA 3d printing light curing forming technology, DLP digital light processing technology and CLIP continuous liquid surface forming technology. Most of these technologies use laser head or projection to cure the liquid photosensitive tree, accumulate layer by layer and finally solidify into the shape of the product, and the product has the characteristics of smooth surface and high precision. Li Dongfang et al. [31] found that photo-curing technology can achieve sub-micron fine printing, making the fabrication of micromechanical structures more convenient.

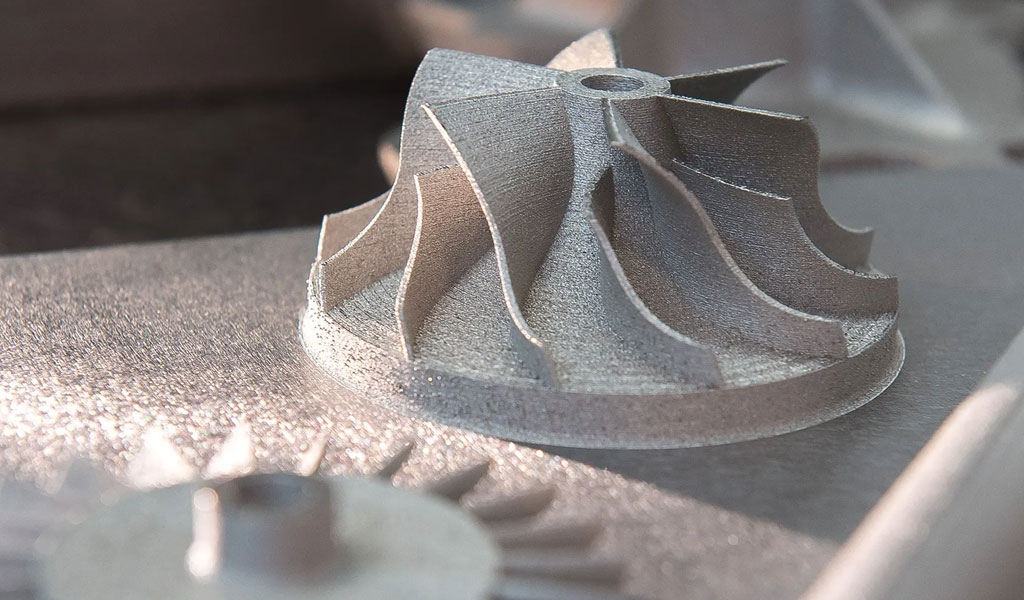

- Powder bed melting: The main technologies are SLS selective laser sintering, SLM selective laser melting, DMLS direct metal laser sintering, MJF multi-jet melting and EBM electron beam laser melting, etc. Most of them make parts by selectively melting each layer of metal powder on a bed of metal powder (or other powder). Parts produced by this technique are characterized by high complexity and, depending on the material and technology, the mechanical properties of the parts produced are better. [32] based on the complementary method of infrared temperature measurement and active control of the laser flux on the powder surface, to achieve efficient control of the temperature distribution of printed parts, and to improve the uniformity and ultimate flexural strength of the material.

- Adhesive spraying: mainly powder bonding in three-dimensional space (BJ3DP), which is a 3D printing technology that finally forms parts by spraying bound solvent layer by layer on the powder bed (the technical principle is shown in Figure 1). -4), this technology has the advantages of wide printing color gamut and many material systems. Nandwana et al. [34] found that the microstructure of the printed product is greatly affected by the powder packing state and the degree of binder saturation, and found that under the condition of supersolidus liquid phase sintering, the complete densification of Inconel-718 alloy can be achieved. , the process can be extended to other metal material systems for application.

- Material jetting: The main technologies are Polyjet polymer jetting, SCP smooth curvature printing and MJM multi-jet molding. These techniques are mainly based on the selective spray deposition of materials in the form of droplets to obtain parts. They have the advantages of high precision, full color and multi-material. Sugavaneswaran et al. [37] found that the strength of the raw material can be significantly improved by adding random orientation reinforcing material to the pure elastomer material designed by computer, and the structural strength in the three-dimensional direction can be consistent.

- Material extrusion: mainly include FFF electrofusion wire-making technology and FDM fused deposition rapid prototyping technology. They mainly heat the filamentary wire through the extrusion head, and then extrude it in a liquid state and accumulate it layer by layer to form the final product. This type of forming technology has the advantages of greening and low cost, but it is not suitable for the forming and manufacturing of large-scale products, and the production accuracy and effect of the product also require further improvement of equipment. Liu et al. [38] found that FDM technology can quickly manufacture metal parts with lower energy consumption and cost, but internal porosity and defects will reduce the corresponding mechanical properties, and it is only suitable for the manufacture of functional products without strength requirements.

- Directed energy deposition: This type of technology mainly includes LMD laser metal deposition forming, LENS laser near net forming, DMD direct metal deposition forming, etc. Mainly through powder feeding or wire feeding, a technology that uses laser or electron beam energy to melt and solidify metal materials on the surface of products, thereby repairing or improving product performance. By optimizing the LENS process parameters, Patrycja et al. [39] realized the near-net shape of the H13 steel mold, the microstructure was uniform and fine, the mechanical properties met the working conditions, and the material hardness was increased from 500 HV to 800 HV.