Iron Casting

Welcome to browse our products list, here we are going to show you our cast iron part. Cast iron is a general term for alloys mainly composed of iron, carbon and silicon. Cast iron is an iron-carbon alloy with a carbon content greater than 2.11% (generally 2.5 to 4%). It is a multi-element alloy with iron, carbon and silicon as the main constituent elements and contains more impurities such as manganese, sulfur and phosphorus than carbon steel.The demand for precision cast iron parts requires efficient and accurate production methods, and sand casting is one of the ways. At BE-CU Foundry, we are capable of various metal casting operations, especially iron sand casting,investment casting, and gravity casting. We produce precision cast iron parts with a wide variety of iron alloys, whether you require a single prototype or batch production, you can get the most cost-effective solution here.

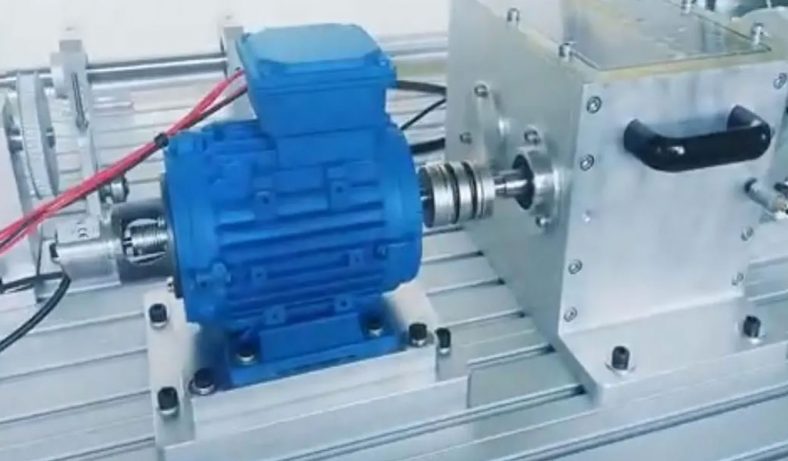

Working with a specialized and seasoned casting foundry can help you save time and money, BE-CU is one of these options. Based on decades of experience in cast iron services, our engineers, designers, and technicians are capable to optimize the product design, prototypes building, material selection, and iron parts production. We also have a well-equipped machine shop and advanced manufacturing facilities to deliver custom cast iron parts with simple or complex geometries, applying various technologies including green sand casting,investment casting,gravity casting,Lost Foam Casting,cnc machining, wire EDM, grinding, or other machining processes, as well as finishing services and more fabrication methods. Whether you want to reach high precision, repeatability, or tight tolerances, our cast iron parts will match your needs. For the best iron casting company, look no further than BE-CU, welcome to send your inquiry to us. We can produce casting iron parts and components made of different types of Grey Iron Casting, Ductile Iron Casting, and more.

Grey cast iron is the most used type of cast iron. Gray cast iron is cast iron with a large amount of flake graphite dispersed in a pearlite (or ferrite) matrix. Slow cooling during pouring can promote graphitization, and gray cast iron can be obtained. It is different from white cast iron because the fracture is often gray-black. Gray cast iron is generally classified as a brittle material, but there is still a certain amount of absorbing external force deformation work and showing a certain toughness. Its carbon content is generally 2.8%~4.0%. Because of its good pouring performance, it is widely used in castings with more complex structures, and even for pouring pressure vessels (such as paper dryers).

Ductile iron is a high-strength cast iron material developed in the 1950s. Its comprehensive performance is close to that of steel. Based on its excellent performance, it has been successfully used to cast some complex forces, strength, toughness, wear resistance. Parts with high performance requirements. Ductile iron has rapidly developed into a widely used cast iron material, second only to gray cast iron. The so-called “replacing steel with iron” mainly refers to ductile iron.

BE-CU Cast Iron Capabilities

- Close design review on tolerances, undercuts, and more details for higher production yields and lower cost.

- If CNC services are required, advanced equipment and extensive experiences will work on less budget and time.

- From concept to prototype to end-use products, our experts will help you with an advantage of speed and reliability.

- Metal surface finishing, quality assurance testing, and more services can be provided to make the castings fit specifications.

- Full-service iron casting factory and high automation reduces the time of each step, ensure the shortest lead time.

BE-CU Foundry has a long history of iron casting production in China, we continue to upgrade our equipment and plant facilities in order to provide our customers with the highest quality products using the latest lost foam casting and sand casting technology. Our modern furnaces can help to reduce production times with faster melting, and enhance our ability to provide competitively priced high quality iron castings.

Our knowledgeable and experienced team provides in-house heat-treating and metallurgical testing to ensure timely production of your order. Below are the pictures of some iron castings we made. Give us an email or call for your needs of custom iron castings.

The flexible welding tooling eliminates the designer’s investment in repeated design and production of tooling.

BE-CU Foundry is the largest iron castings manufacturing and processing base for cast iron plates, cast iron platforms and cast iron workbenches in China. Thousands of qualified products and thoughtful service.The main products are cast iron plate, cast iron platform, riveting plate, inspection platform, assembly plate, basic platform, T-slot platform, three-coordinate plate, welding plate, plate bracket, circular platform, fitter plate, grinding platform, scraping platform , Scribing platform, marble slab, granite slab, machine tool castings, bed castings, ground rails, machine tool workbenches, deflection checker, deflection instrument, cast iron flat ruler and other measuring tools series. Our products are widely used in machinery manufacturing, parts processing, petrochemical, oil refining, power generation, shipbuilding, metallurgy, mining, textile and other industries. Our company has complete product specifications, strong technical force, advanced equipment and reasonable technological process.