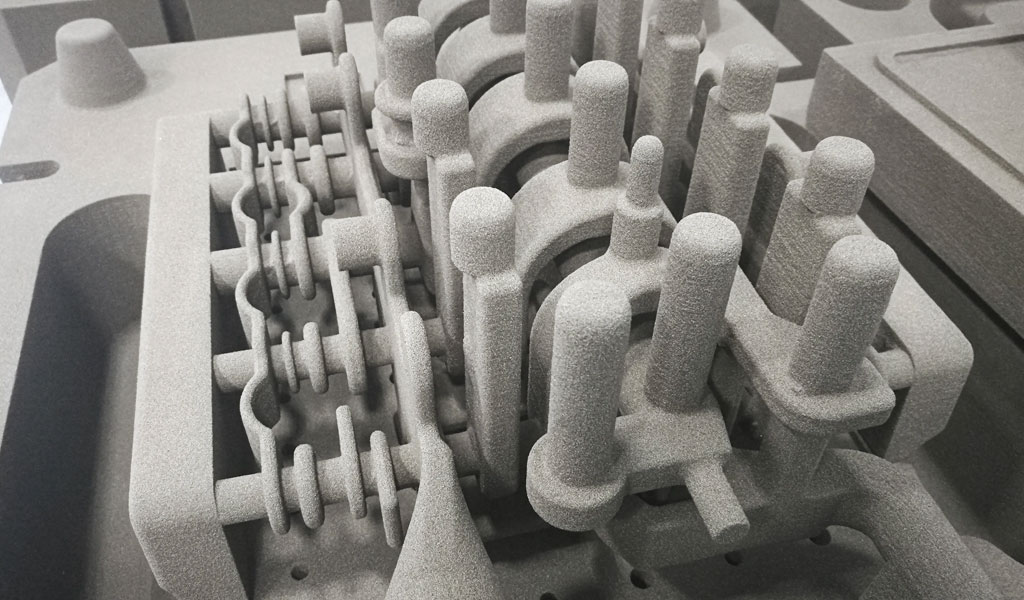

3D printing sand mold is an additive manufacturing technology, which omits the production process of product models and directly prints sand molds. 3D printing sand molds do not consider the demoulding problems such as the drafting slope of traditional models, and complex structures can be combined and printed.

3D printed sand molds are mainly used in the foundry industry. Compared with traditional foundry technology, the application of 3D printing technology in sand mold casting greatly improves the dimensional accuracy of products, enhances the ability to control the size of sand molds, and becomes a precise and controlled link; 3D Printing simplifies complex product sand molds, reduces enterprises’ reliance on high-skilled workers, enhances product quality, and eliminates subsequent product scrapping due to size problems. In addition, the precise size control system can finely control the processing volume of products to ensure product quality.

The machining surface can be designed with a small amount of machining allowance to improve the efficiency of subsequent product processing; the application of 3D printing technology in the field of sand casting provides sufficient guarantee for the flexibility of product design, because the 3D printing sand mold is not affected by the product size Shape constraints, parameters can be changed at any time during the product production process for partial or overall correction, improving the efficiency of product development and verification. The industrial products produced by the traditional investment casting process have high dimensional accuracy, but it is difficult to clean the shell and molding materials of complex inner cavities; while the sand casting process,

The inner cavity is easy to clean. Therefore, combined with 3D printing, it is applied to sand casting sand (core) manufacturing, and its dimensional accuracy is higher than that of traditional sand casting methods, and 3D printing can form products of any complex shape, improve casting quality, and shorten cycle time. Compared with traditional casting technology, it can be It saves a lot of sand casting costs, and the printed products have excellent mechanical properties and are widely used in industrial products.

The advantages of 3D printing sand molds:

- Economical: Sand cores and sand cores can be printed as one piece, eliminating the need to manufacture complex and expensive tooling and casting molds;

- Large print size: the printable sand size is 4000 mm×2000 mm×1000 mm (L×W×H);

- Fast delivery: within 3 working days;

- Printing complex parts: almost not limited by geometric shapes, and can also be printed directly with undercuts;

- High surface quality, dimensionally accurate sand molds and cores: each layer of quartz sand is 300 μm thick;

- Suitable for all sand-castable metals such as aluminum, copper, magnesium, iron, steel and other alloys;

- Sand cores can be mixed: 3D printed cores can be incorporated into conventional sand and vice versa;

- Simple core cleaning: low binder content means easy venting, and core cleaning is similar to traditional methods;

- Prototype production and tooling optimization: 3D printing can be faster, more flexible and more economical for new product development and improved tooling;

The process of 3D printing sand mold compared with the traditional sand mold casting process:

Traditional precision casting technology: mold design → machining → pressing → wax mold or other lost foam → precision casting shell → smelting casting-casting;

3D printing precision casting composite technology: CAD model of complex parts → sand mold/sand core → sand mold making → smelting pouring-casting.

3D printing sand mold material: silica sand, resin sand

Mechanical properties of sand mold: bending resistance 220N/cm²

The surface roughness of the 3D printing sand mold: (Ra)/μm 6.3. In order to reduce the surface roughness of the 3D printing sand mold, the sand mold surface of the cavity was painted with zircon powder coating with a machining allowance of 2±0.5 mm.

3D printing sand mold accuracy: non-machined surface deviation -0.5 ~ 0.7mm, machined surface allowance ≥ 2mm.

Sand mold 3D printing can complete the molding of various complex parts, and the molding dimensional accuracy can be guaranteed within ±0.3 mm. It is not easy for sand mold printing equipment to achieve this accuracy, because the casting needs to be polished later.

3D printing sand mold in the product trial production and research and development stage, the 3D printing response speed is fast, the dimensional accuracy is high, and the single-piece small batch cost is low.

The advantages are prominent, and it can well solve all the needs of the verification stage, until the products are all verified, and after reaching the finalized state, metal models are made for mass production, thereby saving a lot of research and development costs for the enterprise, speeding up the research and development progress, and improving the enterprise’s products. the purpose of competitiveness.